By LISA EISENHAUER

Del Shankle is particularly proud that the award given to CHRISTUS Print Services this summer by a trade organization wasn't for a pretty brochure or for hitting a production milestone. The award his staff got from the In-Plant Printing and Mailing Association

was "for outstanding contributions related to non-production activities within the parent organization."

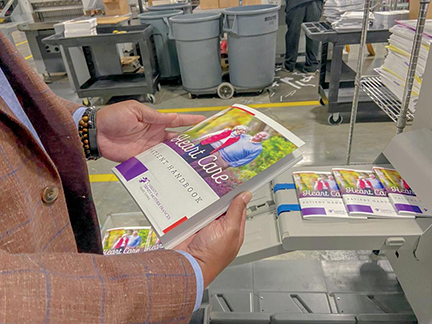

Del Shankle, director of operations, gives a tour of the expanded CHRISTUS Health printing plant in Tyler, Texas.

Shankle heads the printing and mail department as director of operations. He says the honor recognizes that the work at the printing plant he and his nine-person crew operate has a direct connection to CHRISTUS Health's mission to provide the best possible

care with dignity, integrity, excellence, stewardship and compassion in mind.

That connection has been apparent during the COVID-19 pandemic, as the staff has rushed through orders for signage about new policies and mailings to educate patients on how to stay well.

Shankle says the printing plant's staff always is mindful that any cost savings they bring to the system means more money to buy MRIs or other critical equipment and that the patient mailings the plant produces must be handled carefully so as to comply

with privacy laws.

"My team really come to work every day understanding their why," he says. "We don't have to talk about it."

Room to grow

Last fall the print shop moved to a 14,000-square-foot facility in Tyler, Texas, where CHRISTUS Trinity Mother Frances Health System is based. It's double the size of its previous shop in that community. The plant is

attached to that regional ministry although it handles orders from across the parent system, CHRISTUS Health.

Shankle says the larger space allowed the plant to update some of its equipment and create a floor plan with a smoother flow between the massive machines that print, cut, assemble and output 67,000 print orders a year. It also gives the staff more room

to navigate amid those machines.

The presses churn out business cards, brochures, letters, books, signage, banners and more. The products add up to 18 million impressions and nearly 28,000 square feet of materials annually.

Most of the plant's orders come through its digital storefront. The online store has templates for items such as business cards and letterhead that can be personalized to reflect the three dozen or so brands within CHRISTUS with just a few clicks. After

users select products, designs and colors, the system lets them see what the end result will look like before they hit the order button.

The CHRISTUS Health plant handles 67,000 print orders a year, including business cards, brochures, letters, books, signage and banners. The products add up to 18 million impressions and nearly 28,000 square feet of materials.

Shankle estimates that the number of orders the plant is handling has risen about 20% since its move in October. He says the plant could see a 50% increase in production in time based on its new capacity.

Environmental awareness

The printing plant has storage space for paper, acrylic sheets, ink and other materials that previously were stored off-site and trucked in as needed. Having those supplies on-site reduces production time and

transportation costs as well as the plant's environmental footprint because the supplies don't have to be transferred among sites, Shankle says.

Shankle says almost all of the paper used at the plant is from sustainable sources. One of his goals is to have the Forest Stewardship Council certify that all of the Tyler plant's paper stock are made with wood from forests that are managed responsibly.

He also plans to involve the plant in more group purchasing organizations that leverage their combined buying power to get better prices on materials and services and practice environmentally minded material sourcing.

The printing plant is offering its services to CHRISTUS subsidiaries in Chile and Colombia.

Community benefactor

While most of the plant's work is for CHRISTUS, it assists more than a dozen community organizations in the Tyler area with their printing needs. It creates products as in-kind donations or at cost for those groups,

which include the Catholic Diocese of Tyler and the nonprofit Bethesda Health Clinic.

Over the last 18 months, Shankle says that donated or at-cost work equates to a community investment of $62,000. He expects his team to increase its output for community groups in their expanded space.

He sees the community work as another example of how the plant helps CHRISTUS further its mission to extend the healing ministry of Jesus Christ. "Our goal is to help drive down costs so that more resources will be available to our ministries and our

sister organizations to do the things that matter for those that they serve," he says.

Copyright © 2022 by the Catholic Health Association of the United States

For reprint permission, contact Betty Crosby or call (314) 253-3490.